Rope Selection Guide – Which Rope To Choose?

Which rope is best for my needs? There are many different styles of ropes to choose from. Between twisted & braided, natural or synthetic, your options are many. Each one carries it’s own unique properties & characteristics. Our job is to help you select the proper rope you need. This rope selection guide may help!

Manila

Stronger & more economical than true hemp, manila is made with abacá leaves, a close variant to today’s modern banana plant. Made in the Philippines, this natural fiber 3-strand twisted rope is treated with a preservative to increase life & durability. A great low cost rope suitable for decorative nautical landscape projects.

Common Uses

- Landscape Railing

- Decorative

- Pulling & Securing

Pros

- Authentic Natural Fiber

- Low Cost

- UV Resistant

Cons

- Rough on Hands

- Shrinks 15% When Wet

- Rot, Mold, Mildew Over Time

UnManila / ProManila

Made to resemble natural fiber manila, this rope is the synthetic polypropylene alternative. Smooth to the touch with no rough fibers. A great outdoor rope useful for rope handrails, pier & dock barriers, or DIY deck railings.

Common Uses

- Landscape Railing

- Decorative

- Decks, Patios & Piers

Pros

- Won’t Rot, Mildew or Decay

- Low Cost

- Smooth To The Touch

Cons

- UV Degradation

- Non Bio-Degradable

- Lighter Weight Than True Manila

Cotton

Soft & organic, safe for pets & animals. 3-strand twisted biodegradable 100% cotton rope is easy to knot or splice. Great for macramé & the DIY enthusiast, cotton is useful in household decor.

Common Uses

- Macrame

- DIY Projects

- Pets & Livestock

- Crafts & Weddings

Pros

- Safe for Household Pets & Livestock

- Soft & Easy To Splice

- 100% Organic Unbleached

- Washable & Dyable

Cons

- Poor Shock Load Absorption

- Doesn’t Float

- Not Abrasion Resistant

- Absorbs Water

Polypropylene

A general purpose man-made synthetic that won’t rot, mildew or decay. Best suited around water & floats. 3-strand twisted polypropylene is very versatile. Strong, lightweight, & comes in a range of colors.

Common Uses

- Marine Applications

- Low Cost Barrier Rope

- Inexpensive General Purpose

Pros

- Strong & Affordable

- Floats & Won’t Rot

- Lightweight & UV Weather Resistant

- Dielectric Insulator

Cons

- Susceptible To Friction

- Stretches

- Strength

Nylon

With superior strength & high stretch, this abrasion resistant rope is ideal for pulleys or winches. UV rays, chemical exposure & rot do not affect the performance of nylon. Nylon has the highest stretch, strength, and shock absorbency of any synthetic rope.

Common Uses

- Pulleys & Winches

- White Outdoor Landscaping

- Towing & Anchor Lines

Pros

- Very Flexible & Durable

- Superior Strength & Stretches

- Shock & Abrasion Resistant

- Chemical, Rot & UV Resistant

Cons

- Absorbs Water

- Weaker Strength When Wet

Polyester

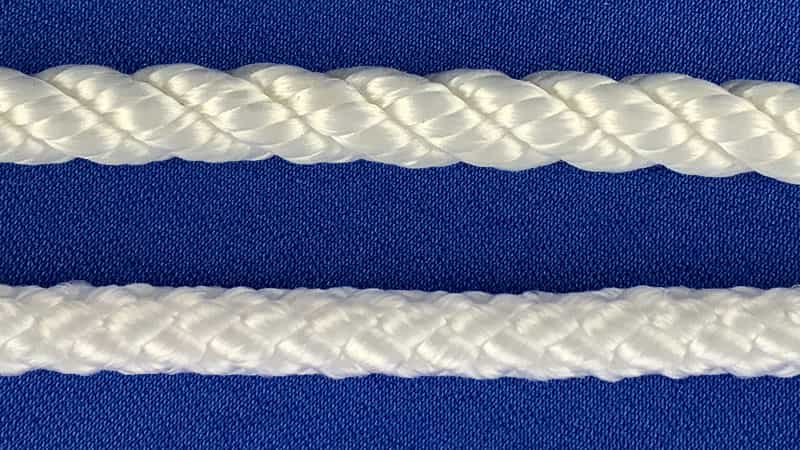

Commonly mistaken for nylon. Polyester has a higher temperature resistance with 10% lower stretch than nylon. Available in braided or 3-strand twisted. This rope maintains it’s strength when wet, & won’t absorb water. A tough, heavy duty all purpose rope.

Common Uses

- Heavy Duty General Purpose

- Dock & Block Rigging

- Boat & Marina Applications

Pros

- High Melting Point

- Won’t Absorb Water

- Retains Strength When Wet

- Strong with Little Stretch

- Rot & UV Resistance

Cons

- Price

- Discolor Over Time

Poly Dacron Rope

This combination rope is a mix between polyester & polypropylene. White with a red tracer. Less expensive than a true 100% polyester, this rope carries the polyester on the outer stands & polypropylene in the inner stands. With less stretch than nylon, this rope has a very high abrasion resistance. Poly Dacron combo rope retains it’s strength when wet.

Common Uses

- Fall Protection

- Rigging & Winches

- Tree Trimming Life Lines

- Sailing & Hoisting

- Rope Ladders

Pros

- Very Abrasion Resistant

- Low Stretch

- Lightweight

- Won’t Shrink When Wet

Cons

- Lighter Than 100% Polyester

- Low Stretch

Superpro Co-Polymer

SuperPro® Co-Polymer Rope is 35% stronger and much more abrasion-resistant than standard polypropylene products. Blending polypropylene and high modulus polyethylene resins, with low elongation characteristics equivalent to pure polyester. This rope is lightweight and provides good handling characteristics and excellent abrasion & UV properties. When you just need a stronger rope than regular polypropylene.

Common Uses

- Ski Tow & Lift

- Messenger & Barge Lines

- Safety Lines/ Water Rescue

- Marine Industries

Pros

- 35% Stronger Than Polypropylene

- Excellent Abrasion Resistant

- Lightweight & Floats

- Easy To Splice/ Great Handling Characteristics

- UV Resistant

Cons

- Cost

- Low Melting Point

HMPE 12-Strand

HMPE Rope (High Modulus Poly-ethylene) 12 Strand has an extremely high strength to weight ratio and has the same or better break strength as wire rope. Easy to handle, this floating rope has a high flex fatigue and is abrasion resistant. HMPE is considered to have the lowest stretch of any synthetic rope. Designed to be comparable to Spectra or Samson’s Dyneema Amsteel Blue.

Common Uses

- Tow & Winch Rope

- Rigging & Pulling

- Slings

- Aquaculture

Pros

- Low Weight To Strength Ratio

- Abrasion Resistant

- Lightweight & Floats

- Easy To Splice

- Chemical & UV Resistant

- Low Stretch

Cons

- Cost

- Low Melting Point

Rope Fiber Selection Guide

| Characteristics | Rating | Nylon | Polyester | Polypro | SuperPro® | Polydac | Manila |

| Strength | Strongest – 1 Weakest – 5 |

1 | 2 | 4 | 2 | 3 | 5 |

| Wet Strength vs. Dry Strength | 85% | 100% | 100% | 100% | 100% | 115% | |

| Shock Load Ability | Strongest – 1 Weakest – 5 |

1 | 3 | 3 | 3 | 3 | 4 |

| Floats or Sinks in Water | Sinks | Sinks | Floats | Floats | Sinks | Sinks | |

| Elongation at Break (Approx.) | 20-34% | 15-20% | 15-20% | 15-20% | 15-20% | 10-15% | |

| Water Absorption | Most – 1 Least – 5 |

3 | 3 | 5 | 5 | 4 | 2 |

| Melting Point | 480° F | 500° F | 330° F | 400° F | 380° F | Chars @ 350° F | |

| Abrasion Resistance | Most – 1 Least – 5 |

3 | 1 | 4 | 2 | 1 | 5 |

| Resistance to Sunlight | Most – 1 Least – 5 |

2 | 1 | 4 | 2 | 1 | 5 |

| Resistance to Rot | Most – 1 Least – 5 |

1 | 1 | 1 | 1 | 1 | 5 |

| Resistance to Acids | Most – 1 Least – 5 |

4 | 2 | 2 | 2 | 2 | 5 |

| Resistance to Alkalis | Most – 1 Least – 5 |

2 | 4 | 2 | 2 | 3 | 5 |

| Resistance to Oil & Gas | Most – 1 Least – 5 |

2 | 2 | 2 | 2 | 2 | 5 |

| Electrical Conductivity Resistance | Most – 1 Least – 5 |

5 | 2 | 2 | 2 | 2 | 5 |

| Flexing Endurance | Most – 1 Least – 5 |

1 | 2 | 3 | 3 | 3 | 5 |

| Specific Gravity | 1.14 | 1.38 | 0.9 | 0.92 | Varies | 1.38 | |

| Storage Requirements | Wet or Dry | Wet or Dry | Wet or Dry | Wet or Dry | Wet or Dry | Dry Only |